NOPAL / NOSTAL – surface embossing

NOPAL® und NOSTAL® are structures for metal foil or metal sheets, enabling an easier, faster and efficient manufacturing.

NOPAL® - nopalised aluminium foil/ sheetNOSTAL® - nopalised stainless steel foil

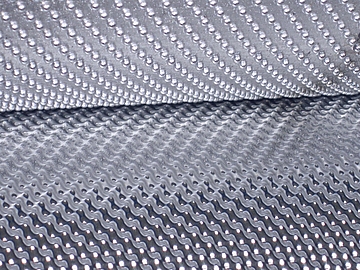

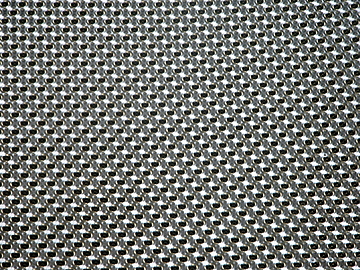

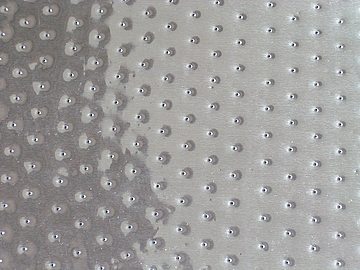

Surface structure version:

- stadard:

up to 3 mm structure height - calotte embossing:

0,5 up to 2 mm structure height - coarse grain:

0,5 up to1 mm structure height - microperforation:

5 up to 60 holes per cm² - Silopal®:

with adhesive coating on the back

Advantages of the special structure:

- less production steps

- low weight

- no edge

- largely formed parts available

- higher stiffness

- saves development time

- saves material

- no degrassing necessary, as conventional deep-drawing processes can be waived

The structure is characterized by the following positive features:

stiffness:

NOPAL® (and NOSTAL®) both have a much higher stiffness, due to the special structure – crossing waves, which are representing a stable vault. There is pre-formed and homogeneous NOPAL® available. The structure of the pre-formed (directional) NOPAL® causes stronger stamping then the structure of the crossing waves. Therefore, directional NOPAL® is in one direction very stiff (corrugated iron) and can easier be adjusted to different formations.

torsional stiffness:

The structure causes significant torsional stiffness. By arranging the studs in alternating and homogeneous fashion and by a varying structural elevation (e.g. 7 mm) this effect is further enhanced.

concertina effect:

One can speak of a "concertina effect“. The tools are getting easier because there is no die cushion necessary. There is no edge.

silencing:

The borne sound is much low-frequency and quieter due to the structure of NOPAL®. With perforated NOPAL® it is additionally possible to reduce the airborne noise.

reduction of weight and re-forming:

By using NOPAL® a much higher stiffness of the forming tool will be produced, which allows to reduce the thickness of the sheeting. Furthermore, NOPAL® enables the use of low-priced tools without an edge.

Contact

Dipl.-Ing. (FH) Gero Seydler

Plant Director

Phone: +49 (0) 6150 / 9678 -51

gseydler@culimeta-automotive.de

Dragan Davidović

Sales

Phone: +49 (0) 6150 / 9678 -16

ddavidovic@culimeta-automotive.de